What is an oil-filled transformer?

What is an oil-filled transformer?

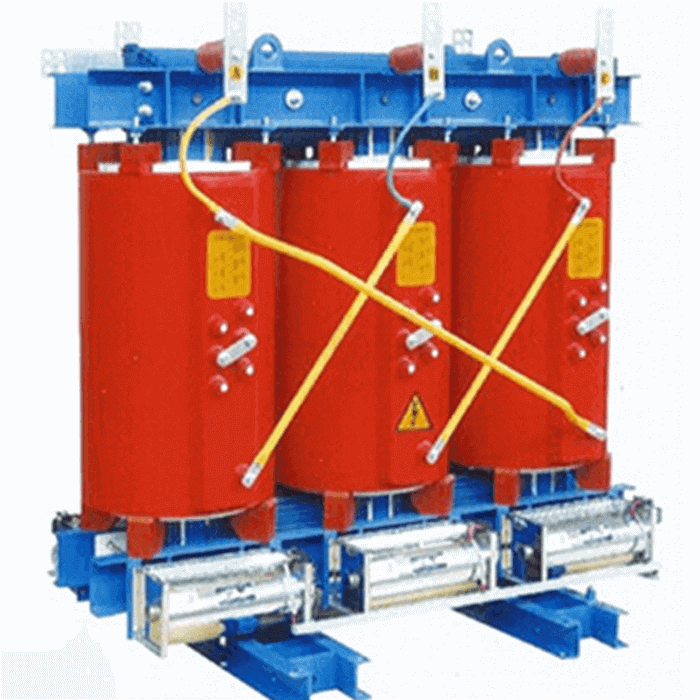

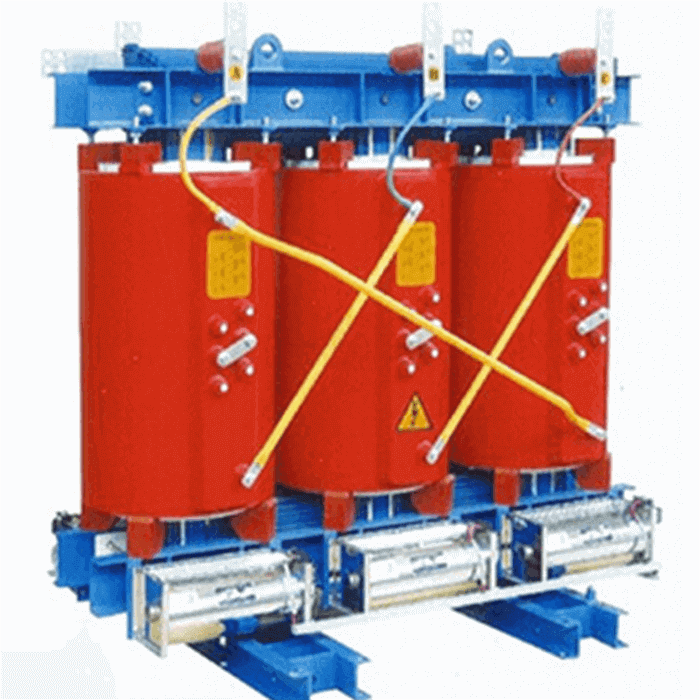

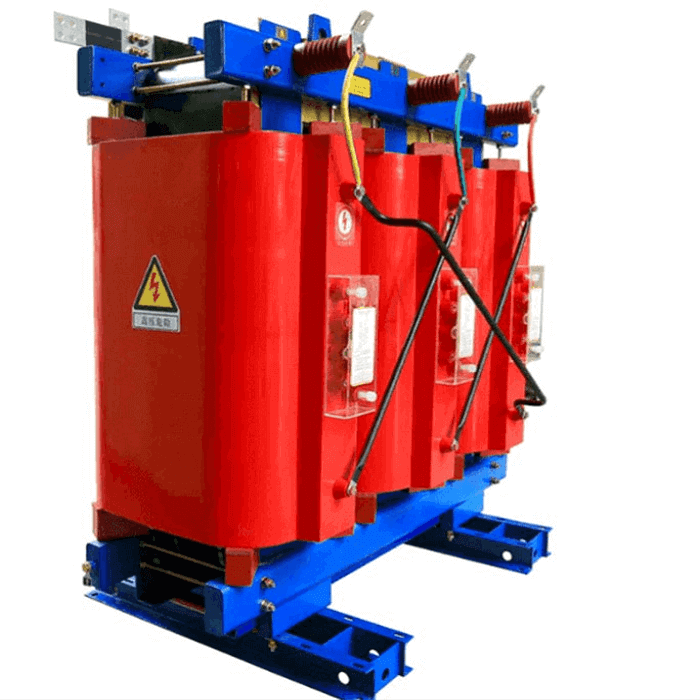

The oil-filled transformer is a kind of structure that is more reasonable, more excellent performance of new high-performance transformer, the three-dimensional volume core due to its three core column is the three-dimensional arrangement of an equilateral triangle, no air gap in the magnetic circuit, winding closer, three-length of the magnetic circuit, and is the shortest, core column cross-sectional area is more close to the circular, thus to further improve performance, reduce loss, noise reduction, Three balance, reduce the third harmonic component, the product is more suitable for urban and rural, industrial and mining enterprises power grid transformation, more suitable for combined transformer and pre-installed transformer substation.

Structure and composition of oil-filled transformer

Three-phase oil-filled transformer is usually used in the main substation of the urban rail transit power supply system. The oil-filled transformer is mainly composed of an iron core, winding, oil tank, pressure regulating device, radiator, oil pillow, gas relay, insulation sleeve, explosion-proof tube and other parts.

1. The iron core

The iron core is composed of silicon steel sheets with good magnetic conductivity, which forms a magnetic flux closure circuit. The primary and secondary windings of the transformer are wound around the iron core.

The transformer core is divided into two types of core and shell structure, currently widely used transformers are core structure. Core type iron core south iron core column and iron yoke. There is an oil passage inside the iron core of the oil-filled callose converter, which is convenient for the oil circulation of the transformer and also strengthens the heat dissipation effect of the equipment.

2. Winding

Winding, also known as cthe oil, is the conductive circuit of the transformer, made of copper or aluminum wire wound into a multi-layer cylindrical shape. The primary and secondary windings are concentrically set on the iron core column. For insulation, the low-voltage windings are generally outside the inner high-voltage windings. Insulation material is wrapped around the wires to ensure that the wires are insulated from each other and the ground.

3. The fuel tank

An oil tank is the shell of othe il-immersed transformer, its role in addition to loading oil, but also used to install other components.

4. Pressure regulating device

The voltage regulating device is set up to ensure the secondary voltage stability of the transformer. When the power supply voltage changes, the voltage regulator is used to adjust the transformer tap switch to ensure the stability of the output voltage of the secondary side. Pressure-regulating device is divided into load regulating device and no-load regulating device two kinds.

5. The radiator

The radiator is mounted on the tank wall, and the upper and lower parts are communicated with the tank through pipes. When there is a temperature difference between the upper oil temperature and the lower oil temperature of the transformer, the convection of oil is formed through the radiator, which flows back to the tank after cooling by the radiator, and plays a role in reducing the temperature of the transformer oil. In order to improve the cooling effect, measures such as self-cooling forced air cooling and forced water cooling can be adopted.

6. Oil pillow

An oil pillow is also called an oil tank. Transformer oil due to temperature changes will occur thermal expansion and contraction, oil surface will rise or fall with the change in temperature. The function of the oil pillow is to keep buffer room for the thermal expansion and contraction of oil to keep the tank always full of oil; At the same time, due to the oil pillow, the contact area between oil and air is reduced, which can slow down the oxidation of the oil.

7. Gas relay

A gas relay, also known as a gas relay, is the main protection device for transformer internal faults. It is installed in the middle of the oil pipe connecting the oil tank and the oil pillow. When a serious fault occurs inside the transformer, the gas relay switches on the circuit breaker and trips the same way; When there is no serious fault inside the transformer, the gas relay switches on the fault signal circuit.

8. Insulation casing

High and low insulating bushings are located on the top cover of the transformer tank, and porcelain insulating bushings are generally used for oil-filled transformers. The function of the insulating bushing is to keep the high and low voltage winding leads well insulated from the tank, and to fix the leads.

9. Explosion-proof pipe

The explosion-proof tube, also known as the safety airway, is installed on the oil tank of the transformer, and its outlet is sealed with glass explosion-proof film. When a serious fault occurs inside the transformer and the gas relay fails, the gas inside the tank will break through the glass explosion-proof film and eject from the safety airway to prevent the transformer from exploding.